Trust Carboline’s expertise and product offerings to safeguard your assets against the pervasive threat of CUI.

By Roy Poelder & Guus Diepstraten

January 2024

Introduction: Corrosion Under Insulation (CUI)

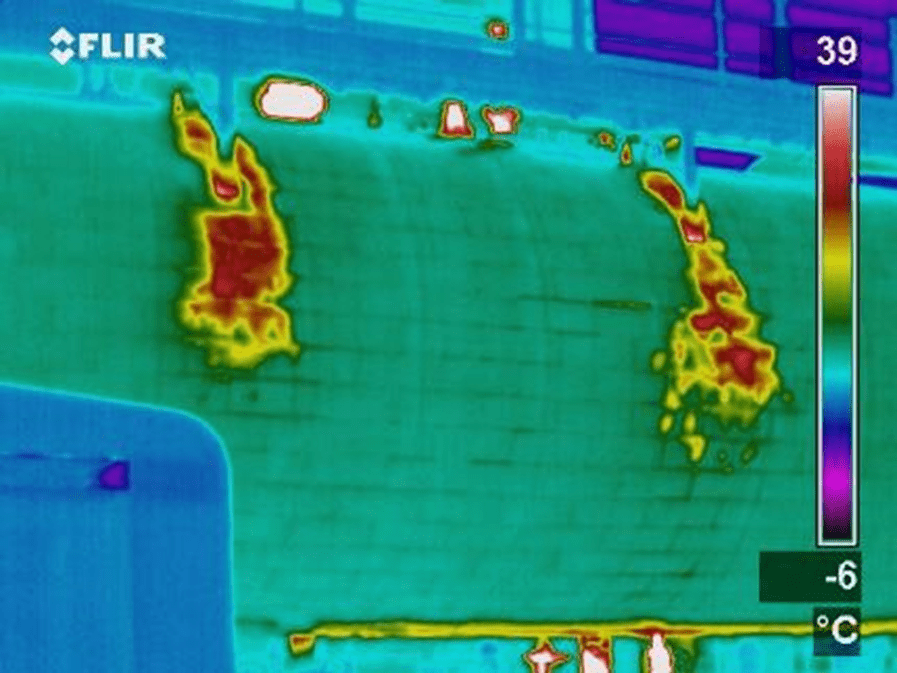

- Invisible Yet Pervasive: CUI, an acronym for Corrosion Under Insulation, poses a significant challenge in industrial settings.

- Unseen Threat: While invisible to the eye, the implications of CUI can be severe and costly.

CUI Inspection

Understanding CUI Potential

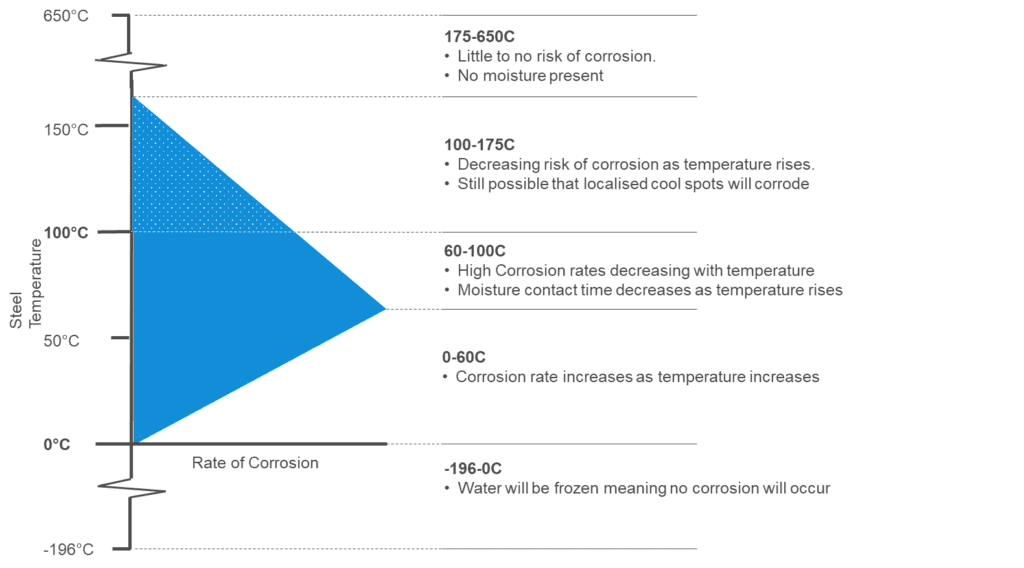

- The Challenge: Elevated temperature environments coupled with insulation present an ideal scenario for corrosion.

- CUI Environment: Despite historical neglect, factors like thermal cycling and wet/dry conditions create a conducive environment for corrosion.

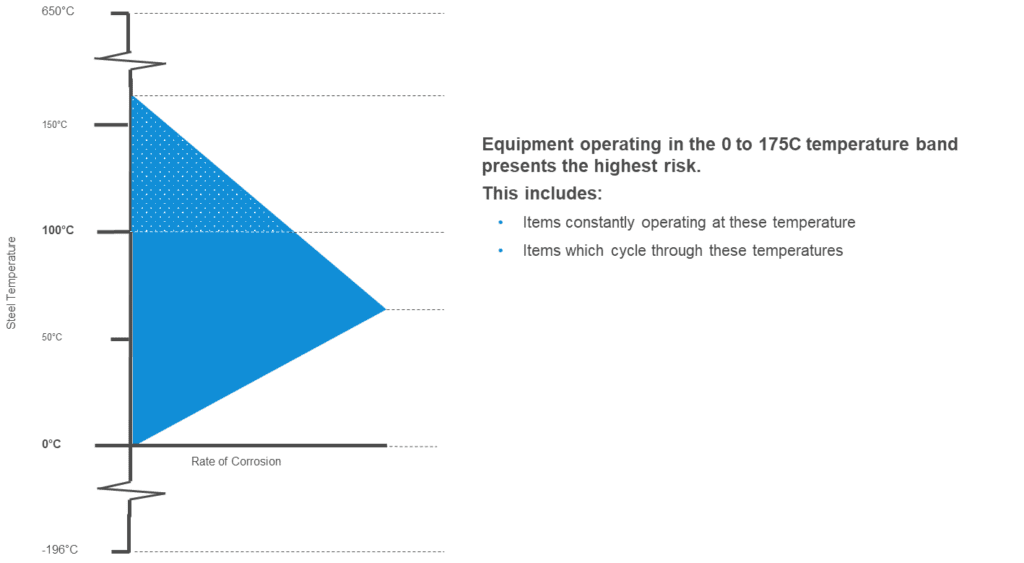

Elevated Temperature Corrosion

Characteristics Contributing to CUI

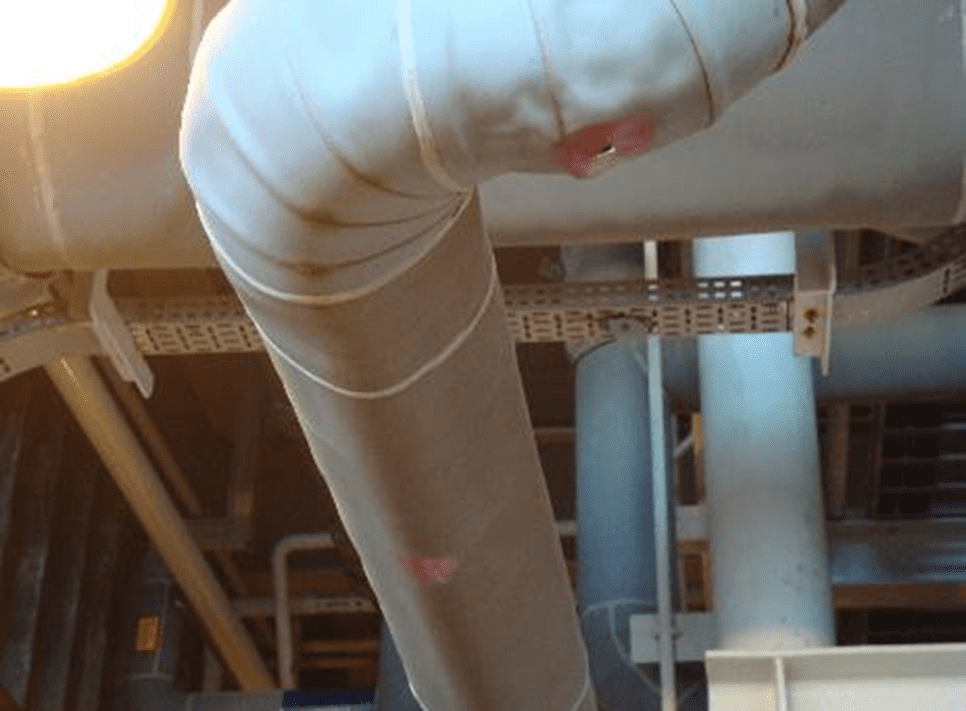

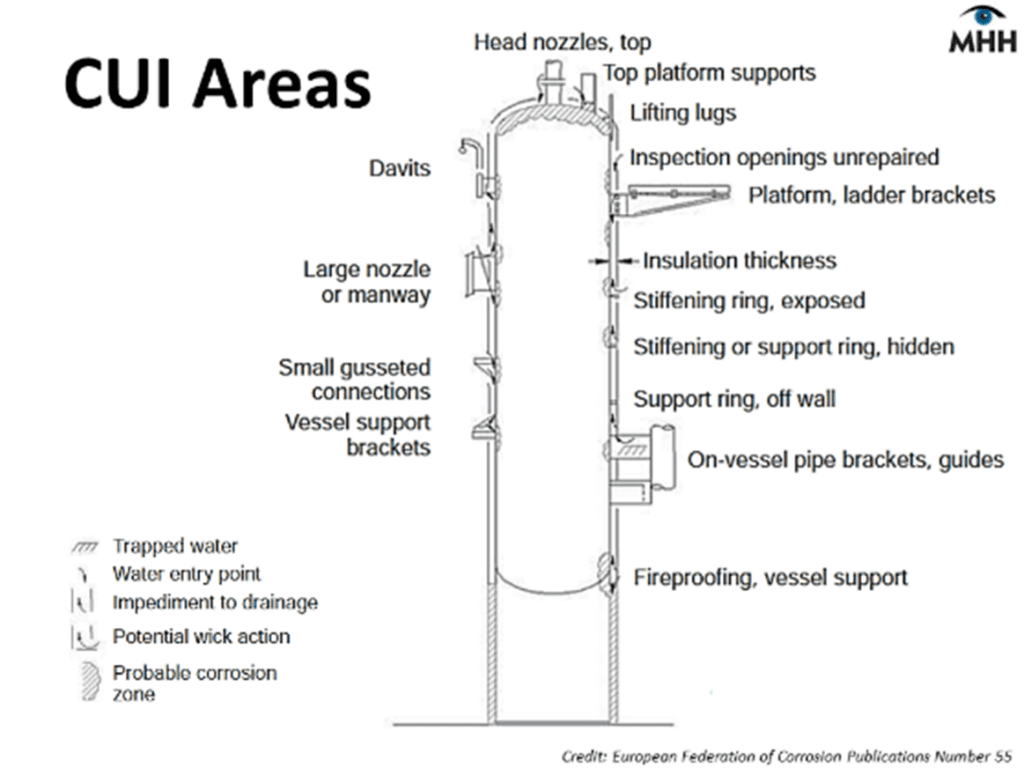

- Cladding Characteristics: Mechanical damage and complex geometries can compromise the effectiveness of insulation systems.

- Insulation Characteristics: Various insulation types can exacerbate corrosion, leading to unforeseen challenges.

- Temperature: Most corrosion occurs between 50°C and 150°C

Practical Implications of CUI

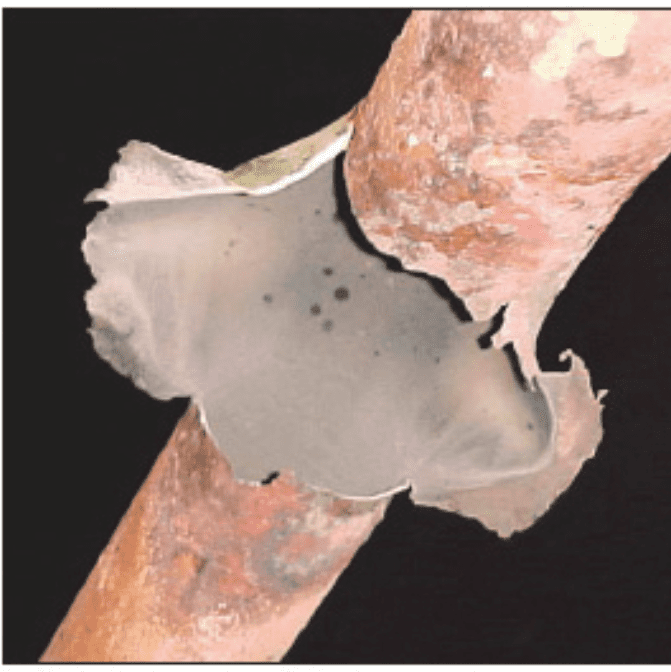

- Rapid Corrosion: CUI can accelerate corrosion rates up to 20 times faster than atmospheric corrosion.

- Hidden Consequences: The concealed nature of CUI can lead to catastrophic failures, particularly in pressurized equipment.

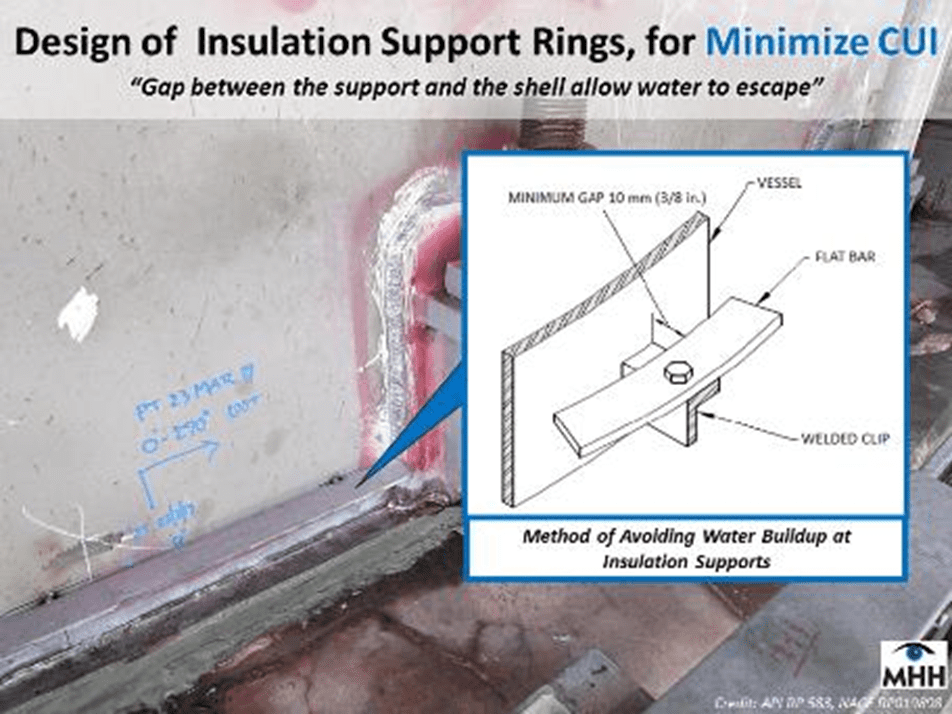

Mitigating CUI Risks

- Prevention Strategies: Effective measures include proper material selection, insulation techniques, and coating applications.

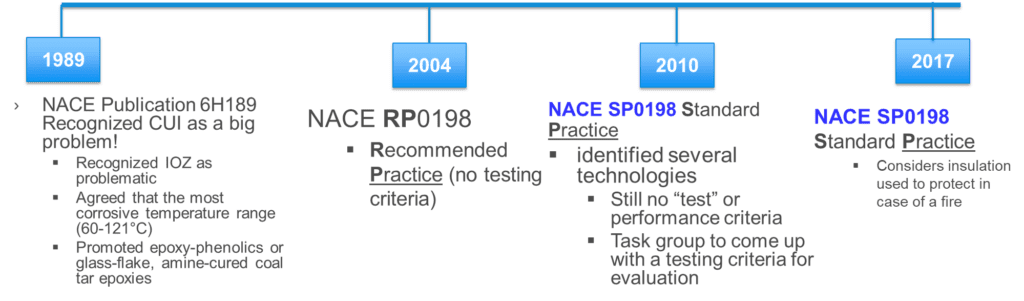

- Industry Standards: Adherence to NACE SP0198 guidelines is crucial in combating CUI.

CUI Examples and Case Studies

- Real-world Scenarios: Explore instances where CUI has caused significant repercussions and learn from past experiences.

- Lessons Learned: Understand the importance of proactive measures in mitigating CUI risks.

The US Chemical Safety Board issued a report in 2008 stating “The highest incidence of reported leaks in refining and chemical industries are due to CUI and not to internal process corrosion.”

Risk Locations

Stainless steel may experience stress corrosion cracking

Product Offerings for CUI Protection

- Thermaline Series: Discover our range of temperature-resistant coatings designed to combat CUI effectively.

- Focus Price List Hi-Heat: Explore our specialized products tailored to address CUI challenges efficiently.

CUI Practices

- Many engineers strictly follow the NACE SP0198 recommendations and use IOZ for all high temperature service above 120°C

- …›BUT … NACE do not recommend the use of Zinc Silicates (or Galvanising) on Carbon Steel under warm, wet Insulation.

- The potential difference between zinc and steel varies with temperature, becoming minimal and even reversing at about 77°C. Above this temperature in fresh or saltwater solutions, the steel becomes anodic to zinc

- “.…Inorganic Zinc Coatings or Galvanising shall not be used under Thermal Insulation in the 50-150°C service temperature range for long term or cyclic service. Zinc provides inadequate resistance in closed, sometimes wet environments.…”

Carboline Nace SP0198 Products

| System | Generic | Temperature Limit | Features |

| Carbowrap Tape | Petroleum tape | Up to 60°c | Easy installation Minimal surface prep Low temperature application |

| Carboguard 890 | Epoxy | Up to 60°c | Versatile epoxy |

| Carboguard 690 | Epoxy | Up to 149°c | Low temperature cure Moisture tolerant |

| Carbomastic 15 | Epoxy | Up to 149°C | Surface tolerant (SSPC-SP3) |

| Thermaline 450 EP | Epoxy-phenolic | Up to 204°c | Most commonly specified |

| Thermaline 450 | Epoxy-novolac | Up to 218°c | Outstanding chemical resistance Glass-flake reinforced 20 year history |

| Thermaline 4001 HeatShield | Inorganic copolymer | Up to 204-540°C | Inorganic polymer Aluminum and MiO reinforced Single package |

Conclusion

- Partner with Us: Trust our expertise and product offerings to safeguard your assets against the pervasive threat of CUI.