Spray on Thermal Insulation Epoxy Coating with excellent anti-corrosive properties!

Carbotherm 551: Revolutionizing Insulative Coatings

Introduction

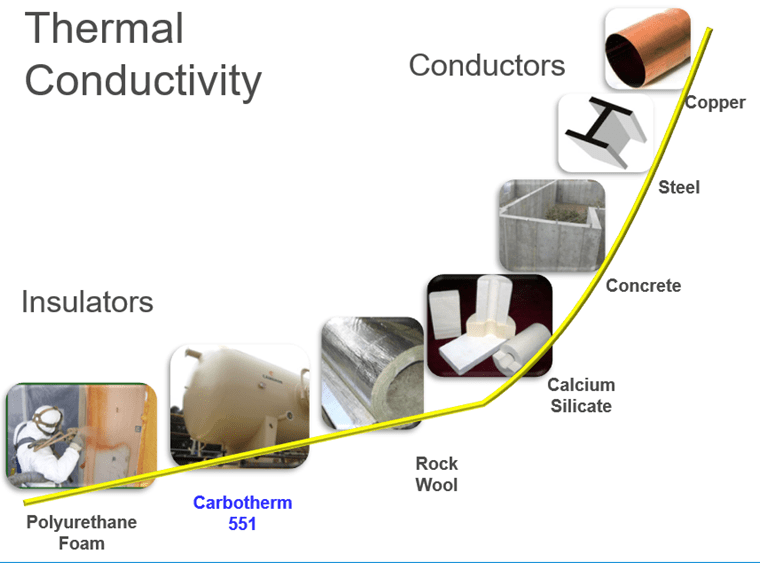

Insulative paints, also known as insulating paints, are engineered to reduce heat transfer and enhance thermal insulation properties. These paints utilize a technology that applies a thermally reflective coating to micro-spheres, blocking heat radiation across a broad spectrum of thermal energy. Carbotherm 551, the industry’s first water-based epoxy insulative coating, presents a groundbreaking solution for various applications, offering unparalleled durability, chemical resistance, and speed of cure.

Product Description

Carbotherm 551 outshines traditional acrylic-based formulations with its superior performance characteristics. This innovative coating is ideal for industrial applications where durability and chemical resistance are paramount. Its versatility extends to multiple applications, including:

- Protection of Workers From Hot Surfaces

- Reducing Effects of Solar Radiation on Steel Substrates

- Providing Insulation to Vessels and Piping

- Minimizing Corrosion Under Insulation (CUI)

Products Type and Differentiation

Part 1: Enhanced Properties

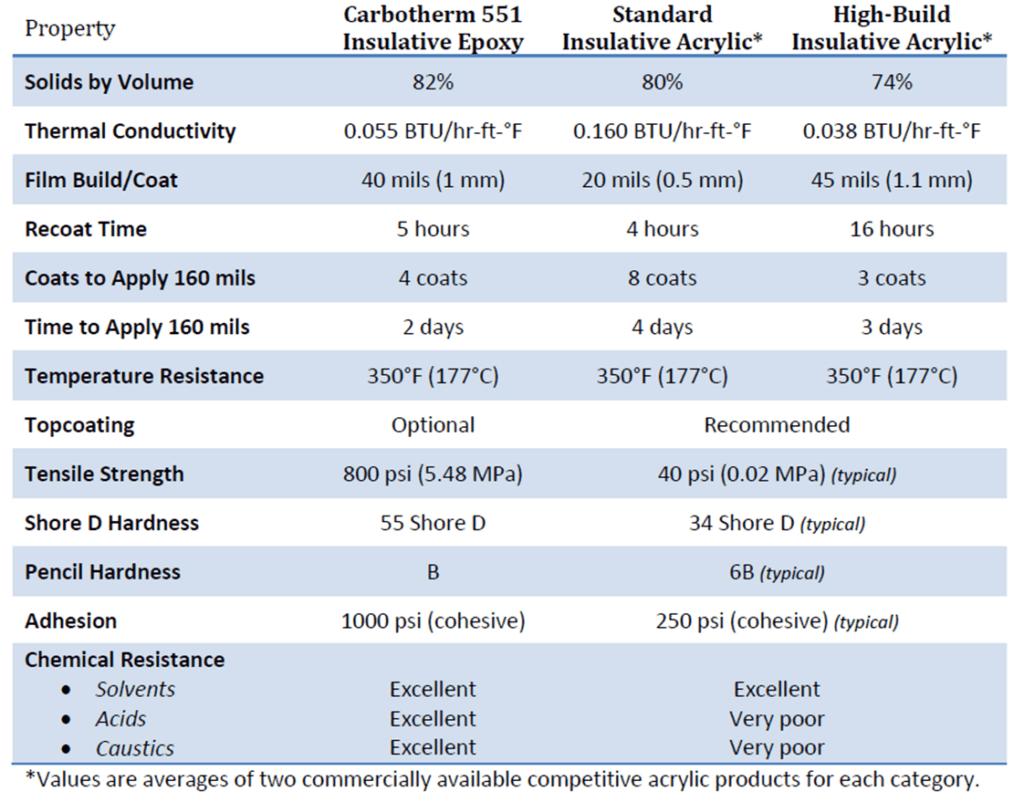

Carbotherm 551 boasts several advantages over conventional insulative acrylics:

- Increased durability in terms of hardness and strength

- Greater adhesion and chemical resistance

- Comparable thermal conductivity with higher film build

- Excellent coverage and minimal shrinkage

- Low odor, water-based formula for safety and ease of use

| Material | k value* |

| Air | 0.0432 |

| Styrofoam/PU foam | 0.0519 |

| Carbotherm 551 | 0.0550 |

| Rock wool insulation | 0.0778 |

| Calcium silicate | 0.0865 |

| Material | k value* |

| Drywall | 0.294 |

| Concrete | 1.730 |

| Stainless steel | 52 |

| Carbon steel | 93 |

| Copper | 694 |

Part 2: Technical Comparison

| Property | Carbotherm 551 | Insulative Acrylics |

| Adhesion | 1000 psi (cohesive) | 250 psi (cohesive) |

| Tensile Strength | 800 psi | 40 psi |

| Hardness | 55 Shore D | 34 Shore D |

| Pencil Hardness | B | 6B |

| Property | Carbotherm 551 | Insulative Acrylics |

| Film Build/Coat | 40 mils (1 mm) | 20 mils (0.5 mm) |

| Recoat Time @75°F | 5 hours | 4 hours |

| 160 mils (4 mm) | 4 coats | 8 coats |

| Time to Apply | 2 days | 4 days |

Part 3: Feature Benefits

Carbotherm 551’s unique features translate into tangible benefits for customers:

- Durable and chemical resistant

- Safe to use with excellent coverage

- Faster application with fewer coats

- Temperature resistance for diverse environments

- Outstanding insulation properties with low “k” value

| Feature | Benefit |

| Epoxy based | Durable; chemical resistant |

| Water-based | Safe to use |

| High film build | Fewer coats; faster application |

| Temperature resistance | -60 to 350°F (-51 to 177°C) |

| Low density; low “k” value | Excellent insulation properties |

| 82% solids | Excellent coverage |

The Technology Explained

Carbotherm 551’s innovative filler-binder formula, utilizing high-strength microspheres and an epoxy binder, ensures improved durability and insulation properties. By trapping air/void spaces within the material, it reduces density while enhancing insulation efficiency.

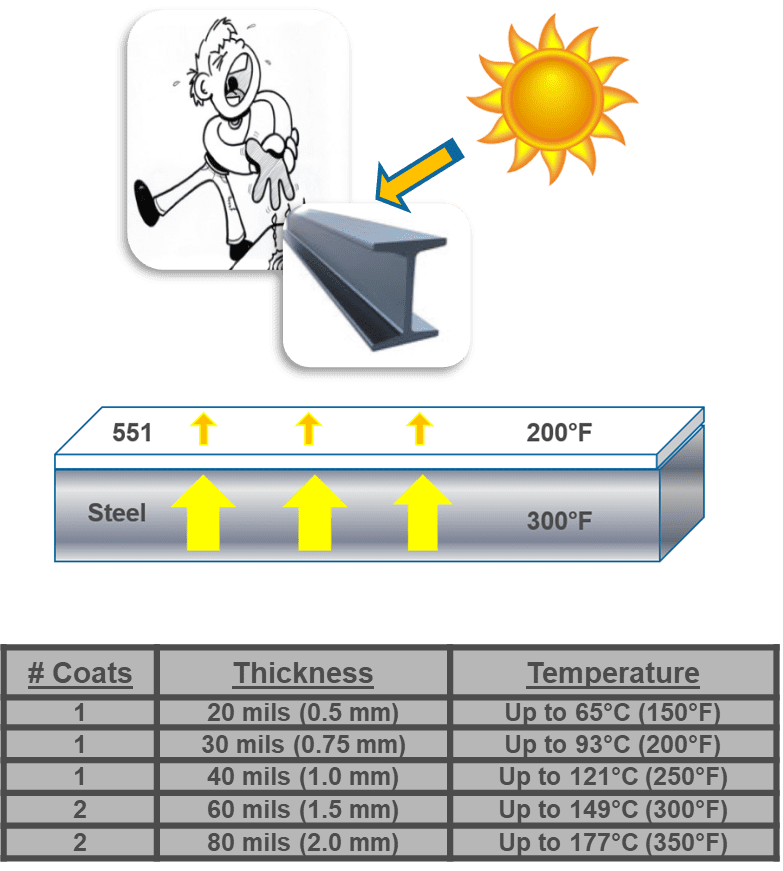

1.Protection of Workers From Hot Surfaces

Carbotherm 551 therefore acts as a Thermal Barrier protecting workers from surfaces operating up to 350°F (177°C) by dramatically reducing the heat transfer through its film:

•Protect workers from first degree burns for 5 seconds on steel substrates

•Normally this is at or above 140°F (60°C) for steel. Steel has a very high “k” value (conducts heat very well).

•This temperature will be higher for materials with lower K-values

The hotter the surface, the thicker the material needed to protect workers.

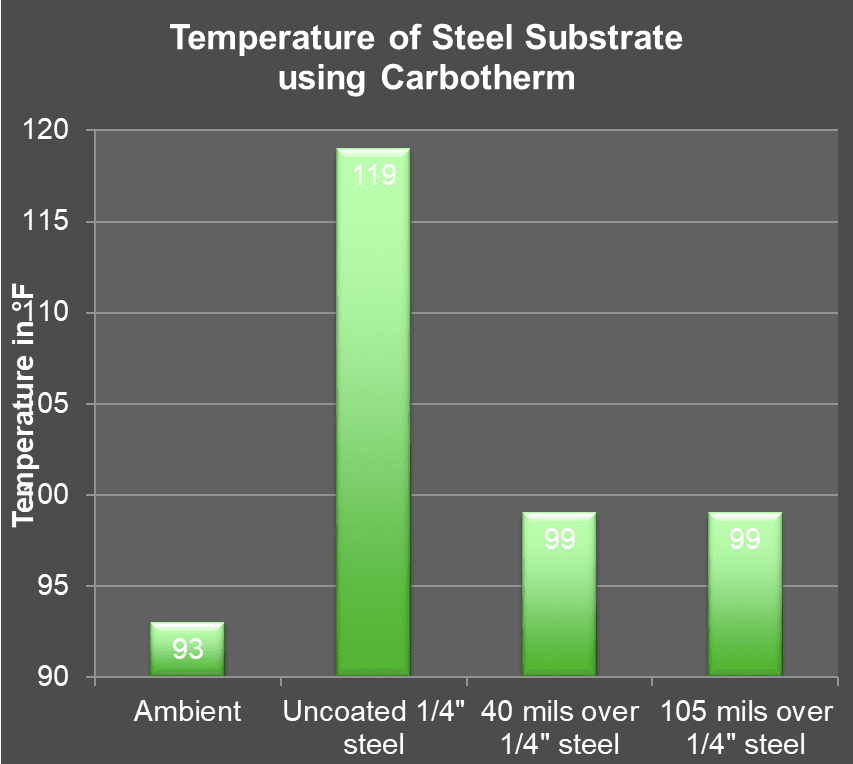

2. Reduce the Effects of Solar Radiation on Steel Substrates

Steel can reach very high temperatures if exposed to sunlight

Another ability of the Carbotherm 551 is also to minimize solar radiation on steel substrates!

| Solar Absorptance | Solar Reflectivity | Specific Heat* | |

| Bare Steel | 0.75 | 0.25 | 450 |

| Carbotherm | 0.15 | 0.85 | 750 |

2. Reduce the Effects of Solar Radiation on Steel Substrates

Carbotherm 551 has 84.7% solar reflectivity that can reduce the thermal increase caused by solar radiation by up to 20-30 degrees Fahrenheit

This ability is often used on storage tanks in order to reduce the “evaporation” of the fluid contained and thus avoiding for the customer production or profit losses due to raw material losses.

3. Provide Insulation to Vessels and Piping

The insulative properties of Carbotherm 551 are excellent. Its thermal conductivity value is exceptionally low and similar to calcium silicate or fiberglass insulation.

While calcium silicate or fiberglass insulation may be impractical or uneconomical to apply in thicknesses commonly used for standard insulation materials Carbotherm 551 is ideal for complex geometries (it is liquid) following the contours of any substrate. As such, its installed cost can result in significant savings over traditional materials in these “hard to insulate” configurations.

Furthermore, not all processes require 80% or more heat efficiency. Carbotherm 551 can be applied at any thickness to achieve the desired heat efficiency. The chart next shows thicknesses needed for hot surfaces and the resultant efficiencies compared to bare steel.

| Carbotherm 551 Thickness/# Coats | Heat Efficiency @ Process Temperature | |

| 250°F | 350°F | |

| 120 mils (3 cts) | 30% | 33% |

| 160 mils (4 cts) | 36% | 40% |

| 200 mils (5 cts) | 42% | 46% |

4. Minimizes corrosion under insulation (CUI)

Water penetration to bare unprotected steel is a recipe for corrosion to occur. This is why NACE has developed a standard practice (SP0198) that specifies a good corrosion resistant coating system be used under insulation. The main differences between Classical Insulation and using Carbotherm 551 are:

1.Classical Insulation (calcium silicate, rock wool, etc):

•Methods are not adhered to the substrate. (do not bond to the substrate)

•Classical insulation methods utilize a two-step/two material process incorporating a jacket material that often allows water to infiltrate and remain trapped (Water eventually finds its way unimpeded to the substrate, picks up contaminants (chlorides and sulfates) along the way, and can initiate corrosion)

Wet insulation is ineffective and can cost owners money in lost heat. Associated CUI problems caused by wet insulation costs industry millions of dollars each year!

2.Carbotherm 551:

•Better barrier (Carbotherm 551 is applied to and directly adheres to the substrate)

•Single product for insulation and protection (Carbotherm 551 provides insulation and prevents excessive moisture from getting to the substrate and initiating corrosion)

Carbotherm 551 does not require metal jacketing or even a topcoat for performance, installation is easier and cheaper while providing both insulation and a moisture barrier in a single product!

Customer Persona & Market Segment

Targeting industries such as Oil & Gas, Petrochemical Plants, Storage Tanks, and Commercial Constructions, Carbotherm 551 appeals to fabricators, OEMs, and constructors seeking cost-effective, high-performance insulation solutions.

Value to the Customer

Carbotherm 551 presents a real alternative to conventional insulation methods, offering increased durability, ease of application, and superior performance. Its unique properties translate into time and cost savings for customers, making it a compelling choice in various industries.

Competitive Landscape

Unlike competitors offering only insulative acrylics, Carboline leads with Carbotherm 551’s unmatched performance and application versatility.

Technical Support

Carboline provides comprehensive technical training and support, ensuring sales representatives possess the expertise needed to educate customers on the benefits and applications of Carbotherm 551.